About Rockstead

Rockstead Knife

The majority of our production is done through the use of high specification NC machines of which we have several, with the skilled engineers tooperate them. We use a wide variety of machines and techniques in the production of our precision knives including our machining centers, wire cutting machines, precision flat-surface grinding machines and NC lathes. Here at Rockstead, we specialize in high tolerance parts manufacturing. In addition to our high-specification machines, we have developed our own highly specialized proprietary machines of which some are tasked with ensuring an unparalleled level of quality control. Our commitment to producing the highest quality knives available can be felt in the smoothness of operation of our pivot mechanism.

The factory custom knife

Rockstead knife is recognized as the factory custom knife. We employ both the use of advanced machining tools, and the craftsmanship of our eight man staff. Our craftsman hand-work the blade after the specular polishing process, providing the same high quality of work as can be expected in a true custom knife. Our factory custom knives are of a completely different quality to mass-produced knives.

BLADE STEEL MATERIAL

The blade steel materials which we use in the production of our knives are YXR7 high-speed steel, and ZDP189 powder stainless steel. Both of these high tolerance cutting implement steels are produced by HITACH Materials Ltd.

①YXR7 (MATRIX HIGH SPEED TOOL STEEL)

The YXR7 matrix high-speed tool steel has outstanding characteristics that are intrinsic to high-speed tool steel.The YXR7 steel has a hardness of around HRc65 while maintaining excellent toughness. This blade don't acquire nickes even when cutting through the dried bamboo. There is one draw back to the use of this steel however, which is that being a high carbon steel, it has a lower tolerance to rust. The way we address this issue with our Rockstead knives, is through our specular polishing process. We are covering the blades made from YXR7 steel with DLC coating. But for the better cutting ability coating in the tip of the blade is removed. So we recommend the blade to be wiped with the cloth after use.

②ZDP189 (POWDER STAINLESS STEEL)

The ZDP189 powder stainless steel is also a high carbon stainless steel, which is specially produced for cutting implements. ZDP189 is able to contain a higher level of carbon than can be contained by dissolution steel. As a result of this, a hardness of HRc67 can be achieved. It is a steel that makes use of nanotechnology in its production. We use ZDP189, but we also use special clad steel consisting of ZDP189 surrounded by VG-10. Please be aware that it is not recommended to use our knives to cut food on the plate, as the knife is likely to cut the plate, and simultaneously cause damage to the knife. You cannot cut ceramic or iron with this knife.

-

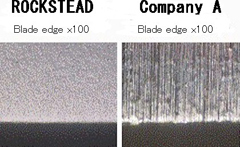

Our blade surface has a mirror finish.

The mirror surface on our knife continues unbroken right to the edge of the blade. There simply isn't another knife in the world like ours. When comparing photomicrographs, the difference becomes apparent. On our Rockstead knives the edge of the blade is completely smooth, while other knives ebges look more like the tip of a saw blade. Roughness at the edge of the blade is the most common cause of nicks.